This note describes an angle encoder, a product by HARSCO. Judging from the product information, this model should be some years old. Used as an accessory on sanding trucks, this angle encoder is not very common.

This is a drawing sent by a customer who wanted a customized batch of replacement products. The customer is in a hurry and wants the delivery to be done in a short period of time. We have prepared the customized solution in the past two days and are waiting for the production on Monday. It is not a particularly difficult product for us.

Introduction to HARSCO-3401495

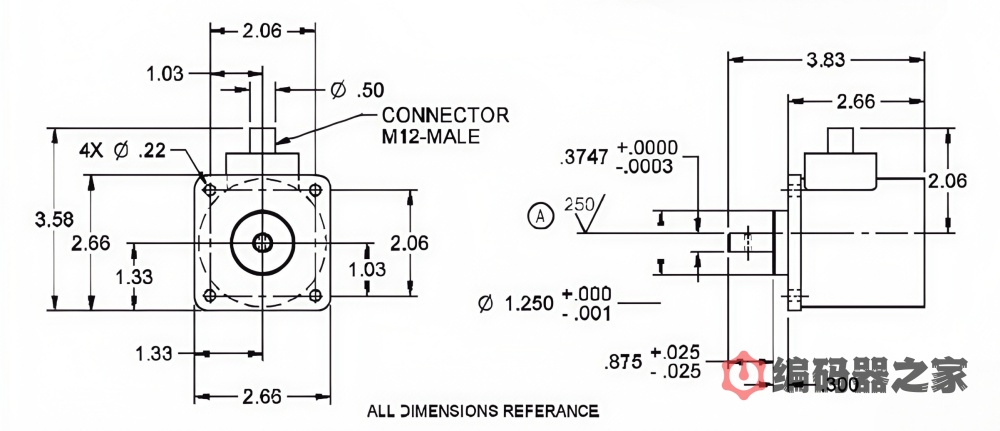

The parameters of this product are not particularly complex, it is an analog encoder with a resolution of only 4096. square flange with a shaft diameter of 3/8 inch. Other dimensions are shown below:

Overall, the parameters of this encoder are rather conventional. It is just a little bit less difficult in the mounting part, mainly in the mounting application. The shaft of this encoder is fitted with a hexagonal nut, which is fixed by means of a pin. This part requires special machining. This means that in addition to the encoder itself, a pin and a hexagonal nut have to be machined.

Introduction to Customized Alternatives

We have a complete solution for encoder mounting surfaces. Square flanges are relatively easy to realize, and the processing of the pin holes is not too complicated, just one more process in the price processing. There is nothing special about it.

For pins and hexagonal nuts, it's a bit more difficult. After all, this part is not our "strong point" and needs to be processed externally. This type of processing is not too complicated, mainly because the quantity is too small to find a suitable service provider.

We have complete mechanical and electrical solutions for the encoder part, which can be used as soon as they are brought to us. Analog encoders are also considered one of our standard products, so it is relatively easy to match them. As long as the installation part is solved, nothing else is a problem.

Just to clarify: the original encoder's socket is on the side near the mounting surface, while ours is positioned near the end. However, this does not affect the use, just to illustrate the difference.

The customer wants our encoder to replace the original encoder in parallel and the installation is a direct plug-in. With this request, we need to make the wiring definition according to the original encoder.

put at the end

The customized replacement of this encoder is quite simple, after all, there are no "difficult" requirements, it is still very easy to have been realized. According to customer feedback, there has not been a replacement for this encoder for many years. Well, now we have a suitable alternative.

If you need a customized replacement for this encoder production, you can contact us. We can help you to realize the alternative application of the product. Since this angle encoder is used for grinding car fittings, which is a requirement for the railroad industry, then the need may be spread all over the world. But it doesn't matter, no matter what country you are in, we can help you accordingly.

There is my contact information at the bottom of the article, both phone and WeChat, so feel free to get in touch.

原文链接:https://www.bmq123.com/en/813.html