One of the SICK encoder series to be introduced today is this oneATM90 EncoderThis is a through-hole absolute encoder to compensate for the lack of the ATM60 series. These are through-hole absolute encoders introduced by sick to make up for the shortcomings of the ATM60 series encoders. The two models in this post are SSI absolute encoders, model numbers ATM90-AXA12X12 and ATM90-ATA12X12.

At first glance, the two encoder models look similar. The difference between these two models is the size of the aperture, that's all. The former has an aperture of 16mm and the latter has an aperture size of 12mm, all other parameters are the same. The other parameters are the same. The only difference is the aperture of the mounting size.

Unfortunately the SICK encoder ATM90 series was discontinued and many spare parts were not available for purchase. The current situation can only be solved by customizing the application with an alternative solution.

Introduction to Customized Alternatives

Let's take a look at the parameter situation of the encoder, we won't talk about the size, we have just said the difference between these two encoders. One is 16mm aperture a 12mm aperture. Let's take a look at the resolution, is 4096 * 4096 SSI communication protocol, M23-12 connector, plug view is counterclockwise. Code value is Gray code, although the official website introduction wrote two kinds: Gray code and binary, but in the manual shows the factory is Gray code. When customizing, if you need when the binary and then do the communication.

The alternative solution we now give is in the form of a blind hole encoder, using a blind hole solution with a 58mm housing and machining a deep hole machine with a diameter of 16mm and a depth of 30mm. This meets the mounting dimensions. However, there is a possibility that the shaft length of the motor will be longer than 30mm during installation, and this part has to be overcome.

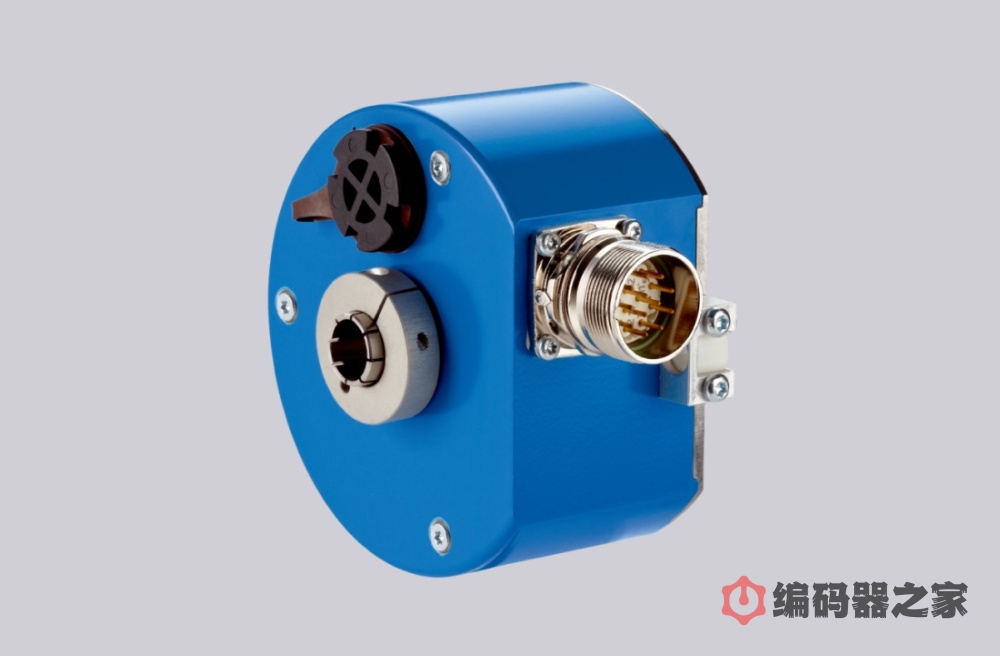

The electrical part of the application is the same and also uses the counterclockwise interface of the M23-12. This solves the application substitution. Let me post a picture of the real thing so you can compare.

Above, is the application substitution achieved by the blind hole solution. This is the stainless steel version, which can also be made in aluminum alloy. In fact, the original is aluminum alloy shell, if the environment is harsh conditions can be considered stainless steel shell.

There are a few other things that are different between the original encoder and the replacement encoder, the shape is different, and another is that the original encoder came with paddles. Nowadays encoders don't have those manual settings. In terms of application it's the same, it's a regular SSI absolute encoder without too many complications.

At this point in writing, I don't think there's much more I need to account for. the SSI encoder is nothing more than that, and it's easy to follow. If you need help solving this area, you can contact the number below.

For alternative customization there are 1:1 application, some are different appearance with the same parameters. Anyway, we only try our best to give solutions.

Original link: https://www.bmq123.com/en/705.html