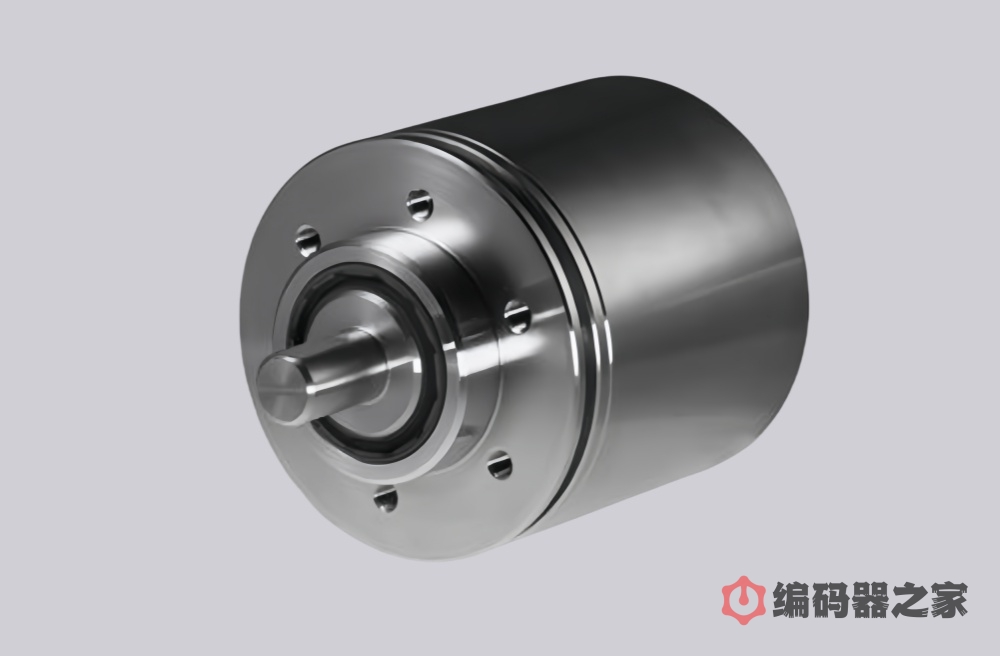

This is a BaumerExplosion-proof absolute encodersM111402. Unfortunately, this encoder has been discontinued, which has had a considerable impact on the purchasing power of many end customers. There is a shortage of these encoders on the spare parts market and no good alternatives are available.

At the beginning of last year, we did this encoder non-standard custom development. It was an alternative solution for a customer, using 1:1 parameters to do a complete non-standard program. Overall, the demand for this product was not particularly high. Therefore, we did not have any extra material. Only made a batch according to the customer's quantity requirements.

In the past few days, two or three more customers came to inquire about this encoder product. As the quantity are relatively small, inquiry only one, we have no way to do production. The main reason is that it is too small, and the cost of doing non-standard for one product is too high.

Introduction to Customized Alternatives

Let's take a look at the parameters of this product.

This is an SSIExplosion-proof absolute encodersThe outer diameter of the encoder is 70mm, the tightening flange, the shaft diameter is 10mm, the tail outlet is 5 meters, and the resolution is 25-bit Gray code. These parameters are the data for the entire encoder. In fact, in terms of communication protocol and resolution, this encoder is easy to realize. We have a complete solution for the electrical part.

The difficulty in customizing this encoder off-standard is the mechanical solution. This is a very uncommon installation size, the outer diameter is 70mm, the diameter of the cam is 40mm. such parameters there is no ready-made mechanical solution to match, can only be re-developed. Plus the material is stainless steel, then the difficulty is even greater.

Last year, we used a supplier to machine the housing in order to speed things up. However, this case is required in quantity. It's not good to give processing for one or two. Finally, we made a batch of 10 units.

In this way, the electrical and mechanical programs were complete, and the delivery was completed very quickly. At that time, it seemed to be about ten days to complete the delivery, the customer is more urgent, we use the urgent order processing.

Non-standard customization process

Now speaking, the customization cycle is going to be a little bit longer. From the second half of last year until now, our machine shop is running on overload. There are too many non-standard products, and scheduling is a bit tight. Individual times have affected our bulk order products. At this point, we will re-communicate the delivery schedule again.

The customization process is also relatively simple, first confirm that the product can be done, and then communicate to confirm the program, and finally signed and the contract. For this encoder, there is no need for these processes. Just confirm that the product is this model can be.

In the past two years, there have been more non-standard customizations of discontinued encoder models. In general, we help people solve application problems whenever we can schedule out time. Three or five quantities of non-standard encoders are practically unprofitable, and only help people to solve the problem of spare parts. We prefer you to apply our standard lot products.

There is no way for us to stock these non-standard products. The main reason is that there are too many models to stock, so we can only customize them according to your actual needs. I hope you can understand this point.

If you need a customized replacement for this X700.M111402 model, contact us first.

Original link: https://www.bmq123.com/en/754.html