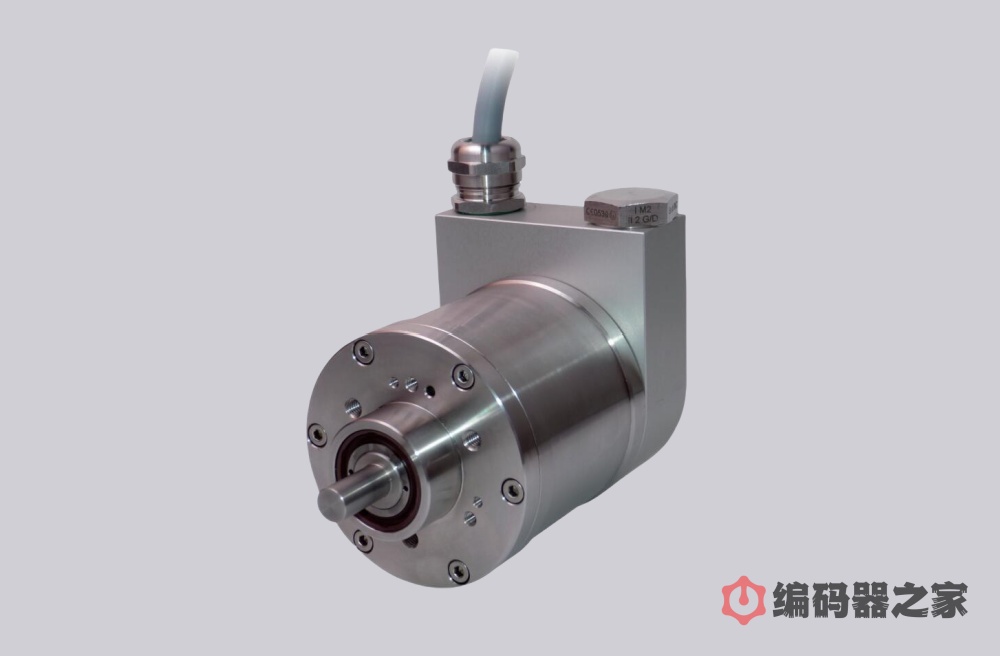

PVS78E-011KRR0BI-0012 Pepperl+Fuchs PROFIBUS single-turn absolute rotary encoder

Pepperl+Fuchs PROFIBUS single-turn absolute rotary encoders

PVS78E

Up to 16 digit mono-turn/ATEX certified/ICEx certified

Fireproof enclosure/removable connecting cap

We offer encoder replacement solutions in the form of off-standard replacements with all 1:1 application parameters, perfect replacements for prototype encoders, solving procurement and other problems. The picture shows the replacement solution.

Technical Data of the Singleturn Absolute Rotary Encoder PVS78E

General specifications

| causality | Detailed information |

|---|---|

| Detection type | optical sampling |

| Equipment type | Singleturn absolute rotary encoders |

| Functional Safety (MTTFd) | 210 a, L10: 7.7 E+9 at 3000 rpm |

| Operating voltage (U_B) | 10 ... 30 VDC |

| No-load supply current (I_0) | Maximum 230 mA at 10 VDC, 100 mA at 24 VDC. 100 mA (24 VDC) |

| biometrics | 16-bit ± 2 LSB, 13-bit ± 1 LSB, 12-bit ± 0.5 LSB |

| output code | binary code |

| Interface Type | PROFIBUS DP |

| decision (of a congress) | Up to 16 bits per revolution |

| transmission rate | 0.0096 ... 12 MBit/s |

| standards-compliant | PNO Profile 3.062, RS-485 |

Environmental protection and durability

| causality | Detailed information |

|---|---|

| Protection level | DIN EN 60529, IP66 |

| Climate testing | DIN EN 60068-2-78, no moisture condensation |

| radiated interference | en 61000-6-4:2007/a1:2011 |

| noise immunity | EN 61000-6-2:2005 |

| impact resistance | DIN EN 60068-2-27, 100 g, 3 ms |

| seismic defenses | DIN EN 60068-2-6, 10 g, 10 ... 2000 Hz |

Approvals and certificates

| causality | Detailed information |

|---|---|

| IECEx Certification | Equipment protection class Gb, IECEx ITS 15.0061X |

| ATEX Certification | Equipment protection class Gb, ITS 15 ATEX 18372X |

environmental conditions

| causality | realm |

|---|---|

| operating temperature | -40 ... 70°C (-40 ... 158°F) |

| Storage temperature | -40 ... 85°C (-40 ... 185°F) |

Mechanical specifications

| causality | Detailed information |

|---|---|

| makings | Housing, flange anodized aluminum, shaft: stainless steel 1.4404 / AISI 316L |

| mass (in physics) | approx. 2600 g (combination 1), approx. 3900 g (combination 2) |

| rotation speed | Maximum 3000 min^-1 |

| moment of inertia (mechanics) | 180 g cm^2 |

| Starting torque | ≤ 4 Ncm |

| shaft load | Axial: 60 N, radial 80 N |

connectivity

| causality | Detailed information |

|---|---|

| cable connection | ∅9.6 mm, 7 pole, terminal box for connection |

Operating modes and parameters

| Operating modes/parameters | clarification |

|---|---|

| direction of rotation | Programmable, cw Ascending or Descending |

| zoom function | Supports programmable resolution per revolution |

| preset function | Supports programmable presets |

| diagnostic report | Support for extended diagnostic reports |

| high speed transmission | Support, optional units |

| limit switch | Programmable Limit Switches (Software) |

| debug mode | Debug Mode Support |

this paper was written by Encoder Home Posted in. Encoder HomePlease maintain the integrity of the article and include the source of the article (Encoder House) and a link to this page.

Original link: https://www.bmq123.com/en/1056.html

Original link: https://www.bmq123.com/en/1056.html